How to define iron loss parameters ?

19

1. Iron losses model - Main principles

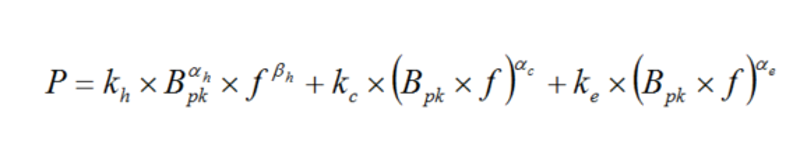

The mathematical formula used in Altair FluxMotorTM to compute the iron losses is:

Note: Iron loss model is only used for lamination.

Label |

Definition |

kh |

Hysteresis loss coefficient |

αh |

Exponent of B for the hysteresis losses |

βh |

Exponent of f for the hysteresis losses |

kc x kαc |

Classical loss coefficient – Sine wave |

kc |

Classical loss coefficient – Any wave Automatically computed from the sine wave value – The field is grayed out. |

αc |

Exponent of B and f for the classical losses |

Ke x kαe |

Excess loss coefficient – Sine wave |

ke |

Excess loss coefficient – Any wave Automatically computed from the sine wave value – The field is grayed out. |

αe |

Exponent of B and f for the excess losses |

Note:

The formula above is not homogeneous with considered the units.

Indeed, it represents a correspondence between the flux density associated with the frequency and the resulting iron loss amount.

The coefficients listed above are completely independent of units.

In Altair FluxMotorTM, P represents the amount of iron losses per cubic meter. This quantity is computed by considering B in Tesla and f in Hertz. The coefficients are always defined by considering these reference units.

The user can use other units for defining the iron losses or flux density for example. In Altair FluxMotorTM the corresponding quantities are transformed to come back to original units (Tesla, Hz and W/m3).

When creating a new material or when editing the properties of an existing one, a tab is dedicated to the magnetic data. In this tab, iron loss coefficients must be given.

|

|

|

Definition of iron loss coefficients |

|

| 1 | In the tab dedicated to magnetic data, a data table allows to define iron loss parameters. The users can fill this form when they know the values of the parameters. |

| 2 | It is possible to move forward or backward to other tabs describing all the physical properties of lamination. |

| 3 | When the users do not know the values of the parameters, they can use the function “Fit” to find relevant values to set. This function is described below. |

2. How to define iron loss parameters?

2.1 Overview

Three main methods are provided to help the users find the relevant values to consider for the iron loss parameters. The choice of the method depends on the data that the user has for the lamination to consider.

Three cases are considered:

-

One measurement point is characterized: Amount of iron losses corresponding to the values (frequency, induction).

-

Two measurement points are characterized: Amount of iron losses corresponding to the values (frequency, induction).

-

Several curves of iron losses in function of flux density for different values of frequency which corresponds to a map of Iron losses in f - B plane (where f= frequency and B=flux density).

2.2 Case 1: From one measurement point

|

|

|

Definition of iron loss coefficients – from one measurement point |

|

| 1 | Dialog box dedicated to define the iron loss parameters. Located in the magnetic data tab when creating a new material or when editing the properties of an existing one. |

| 2 | Choice of the method to find iron loss parameters (1 point in this example). |

| 3 | Measurement characteristics:

|

| 4 | When input parameters characterizing the measurement point are defined, click the button Fit to run the optimization process. This process computes the set of iron loss parameters that allow targeting the considered measurement point. |

| 5 | The resulting iron loss input parameters are deduced and displayed in the result table and the corresponding curve Losses versus B (magnetic flux density) is displayed. Note: The values can be modified inside the table and the resulting curve is displayed below. |

| 6 | It is possible to select a frequency to visualize the behavior of the resulting iron loss curve. Note 1: Write a new frequency or user can select the frequency by expanding the menu. Note 2: In the current example, the selected frequency equals the frequency set as input. The targeted measurement point (in red) is superimposed to the resulting iron loss curve. |

| 7 | Validation of iron loss parameters is achieved when clicking on this button. It is possible to cancel the computation of iron loss parameters. |

2.3 Case 2: From two measurement points

|

|

|

Definition of iron loss coefficients – from two measurement points |

|

| 1 | Dialog box dedicated to define the iron loss parameters. Located in the magnetic data tab when creating a new material or when editing the properties of an existing one. |

| 2 | Choice of the method to find iron loss parameters (2 points in this example). |

| 3 | Measurement characteristics to give for each measurement point:

|

| 4 | When input parameters characterizing the two measurement points are defined, click on the Fit button to run the optimization process. This process computes the set of iron loss parameters that allow targeting the considered measurement points. |

| 5 | The resulting iron loss input parameters are deduced and displayed in the result table and the corresponding curve Losses versus B (magnetic flux density) is displayed. |

| 6 | It is possible to select a frequency to visualize the behavior of the resulting iron loss curve. In the current example, the selected frequency equals the frequency set as input. The targeted measurement points (in red) are superimposed on the resulting iron loss curve. |

| 7 | Validation of iron loss parameters is achieved when clicking on this button. It is possible to cancel the computation of iron loss parameters. |

2.4 Case 3: From a map (file input)

|

|

|

Definition of iron loss coefficients – from a map |

|

| 1 | Dialog box dedicated to define the iron loss parameters. Located in the magnetic data tab when creating a new material or when editing the properties of an existing one. |

| 2 | Choice of the method to find iron loss parameters (from a file input (map) in this example). |

| 3 | Select the Excel file inside of which several curves of iron losses with flux density functions are available for different values of frequency are defined. An example of file is shown below. |

| 4 | When the Excel file is selected, click on the Fit button to run the optimization process. This process computes the set of iron loss parameters targeting the considered measurement points. |

| 5 | The resulting iron loss input parameters are deduced and displayed in the result table and the corresponding curve Losses versus B (magnetic flux density) is displayed. |

| 6 | It is possible to select a frequency to visualize the behavior of the resulting iron loss curve in a wider range of frequencies. In the current example, the selected frequency equals the frequency considered in the Excel file. The targeted measurement points (in red) are superimposed on the resulting iron loss curve. |

| 7 | Validation of iron loss parameters is achieved when clicking on this button. It is possible to cancel the computation of iron loss parameters. |

Example of an Excel file to define the curves of iron losses in function of flux density for different values of frequency.

That corresponds to a map of Iron losses in f - B plane (where f= frequency and B=flux density).

|

|

Example of an Excel file to define iron loss parameters from a map |

Note: The columns with the larger number of rows must be written first. At least three columns with the same number of rows must be written. In the example above, there are four columns with twenty rows.